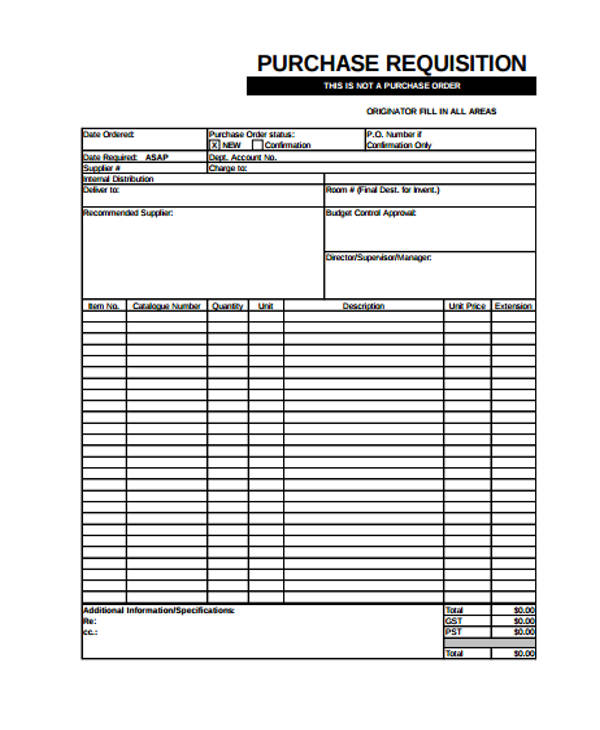

It also means that inventory items and materials picked from inventory are accurate. A form requiring that a specified item be issued from an organization’s stores for a specified use. Such a requisition is usually a prime document, which must be properly completed and authorized. It will contain a description of the material, commodity what are t accounts definition and example code, job number or accounting code, and the value of the material transferred from store to expenditure. The rates and amounts of materials are entered in the materials requisition form by the Costing Office. A purchase order is a contractual agreement companies use when ordering goods and services from an external vendor.

Cleaning Supply Order Form

Our easy-to-use Internal Audit Request Form template is the perfect solution. Quickly gather essential information from your team, track audit details, and ensure smooth communication between departments. Use this free template to effortlessly initiate, track, and analyze internal audits, enhancing your company’s compliance and operational efficiency. The person who is requesting the materials will keep a copy of the form, as will the warehouse staff.

What Is Material Requisition?

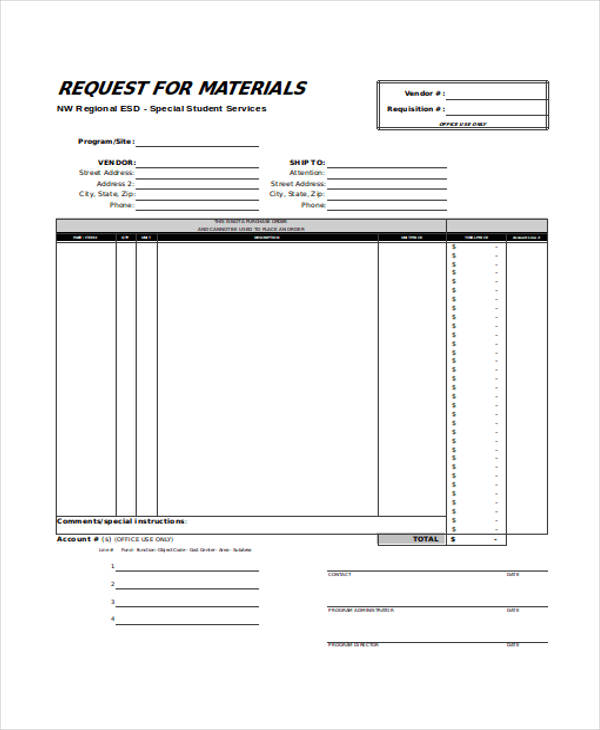

A Material Requisition Form PDF streamlines the process of requesting materials, ensuring accuracy and traceability. It’s vital for managing Stock Requisition Form submissions, ensuring timely and efficient material allocation. A Book Supply Order Form is a form designed to receive orders for purchase transactions which is provided by the supplier of goods to the purchaser. This form is designed to eliminate the process of calling to the supplier and going through a lengthy conversation of having a list of books to be ordered and re-reading them for clarifications. By having this Book Supply Order Form, the customer immediately provides the accurate list that the customer wants, and timely be provided by the supplier.

Responsible Sourcing: How Supply Chain Sustainability Can Benefit Everyone

A financial professional will offer guidance based on the information provided and offer a no-obligation call to better understand your situation. Someone on our team will connect you with a financial professional in our network holding the correct designation and expertise. This team of experts helps Finance Strategists maintain the highest level of accuracy and professionalism possible. At Finance Strategists, we partner with financial experts to ensure the accuracy of our financial content. Finance Strategists has an advertising relationship with some of the companies included on this website.

- Procurement starts with materials planning and ends with payments, but at the end of the day, the whole point of the process is to ensure field teams get the right materials at the right time.

- After receiving a materials requisition form, the store-keeper issues the required materials to the correct job and enters the details in the appropriate bin card.

- Effortlessly collect and review project details, financial breakdowns, and justifications in one place.

- Leverage mobile notifications from your procurement software to keep field teams updated on open orders so they can stay focused and manage expectations.

- A company’s internal purchase requisition form is for employees who wish to request supplies for their departments or themselves.

Once the requisition form is completed, it should be reviewed and approved by the appropriate personnel. This may include the inventory manager, the purchasing manager, or the finance department. Once approved, the form is forwarded to the inventory department for processing.

Define clear steps for creating, tracking, and fulfilling material requests so everyone knows what’s expected along the way, no matter which jobsite they’re on. This will save time with predictable collaboration across the team and prevent a lot of frustration. When there are missteps, it will be much easier to identify what went wrong and how to improve the process going forward. Procurement starts with materials planning and ends with payments, but at the end of the day, the whole point of the process is to ensure field teams get the right materials at the right time. Requesting is one of the most critical steps to keep projects on track and prevent bottlenecks. When you do it right, material requisition improves efficiency and transparency by clearly stating what you need and why.

The requisition form is also used to allocate production costs to goods in process, since not all inventories in process will finish in the current year. As you’ll always have goods in the production process, the forms help allocate costs and values to these materials so you can keep an eye on your bottom line. Information on the requisition is used to update the stores record card, also known as the bin card, and the stores ledger. It’s also used to determine the direct materials used on various jobs or products, along with the indirect materials used by various cost centers. The process of ordering, storing, and using a company’s inventory, including raw materials, components, and finished products, in a way that minimizes costs and meets customer demand. A form used by agencies to request DES to order materials, supplies, and equipment, or to request an amendment of a previous requisition.

A Material Requisition Form is a document used by various departments within an organization to request materials or supplies needed for their operations. It acts as a formal request to the inventory or procurement department, detailing the specifics of the materials required, such as quantity, description, and the purpose of the requisition. This process ensures that resources are allocated efficiently and responsibly, supporting the smooth functioning of organizational activities.

Kommentare